Product Information

Tx300P-1800

- Liên hệ để biết giá

Next is - To The Ultimate On-Demand Production -

Create your own design fabric!

Owing to the widespread use of the Internet, the number of orders for personalized/customized design products has been increasing.

To meet the latest market needs, Mimaki developed the Tx300P-1800. This entry-level model fits perfectly in places with limited floor space, such as design studios or school facilities.

The Tx300P-1800 delivers high-quality printing on a wide range of textiles.

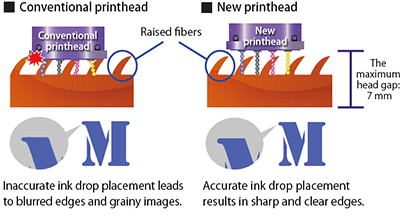

- New printhead allows printing on various types of textile

While maintaining high-quality printing, high gap settings of the printhead allow printing on not only thick textiles but also various woven patterns or raised fiber surfaces.

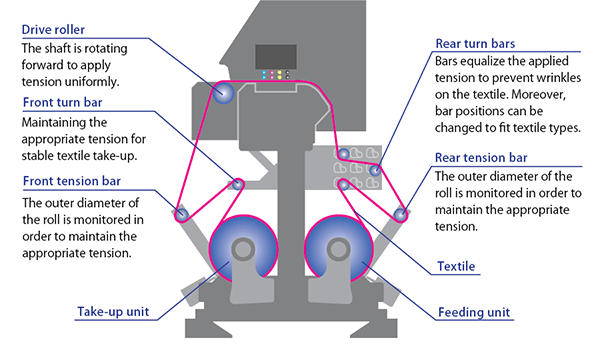

- Reliable textile feeding mechanism ensures stable printing

Reliable and unique feeding mechanism including front and rear tension bars ensures stable textile transportation for providing quality printing.

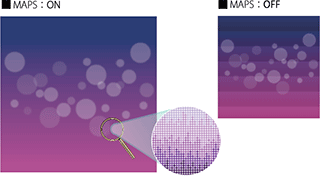

- Mimaki’s print technologies for achieving beautiful printing

- Mimaki Advanced Pass System 4 (MAPS4) reduces banding.

- Superior inkjet technology

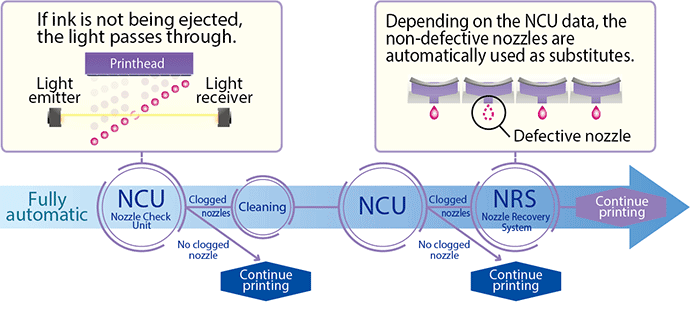

- Uninterrupted printing solutions

- Nozzle Check Unit (NCU) automatically detects and cleans clogged nozzles.

- Nozzle Recovery System (NRS) uses only good nozzles as substitutes, when the clogged nozzles are not recovered after cleaning.

- Mimaki Bulk Ink System 3 (MBIS3) for long-time continuous printing.

- Maximum print speed (68 m2/h) achieves high productivity

68 m2/h maximum print speed with 4-color printing and 37 m2/h with 6-color printing.

- 68 m2/h: 4-color draft mode / 540 × 360 dpi / 2 pass (Sb420 ink)

- 37 m2/h: 6-color draft mode / 540 × 360 dpi / 4 pass (Sb420 ink)

- A wide range of textile inks

Mimaki offers five ink types—sublimation, dispersant, pigment, reactive, and acid—to meet various application needs. For providing affordable ink prices, inks are packed in large volume packs (2 liters) and can be installed to MBIS3.

- High-performance RIP software TxLink3 Lite

The TxLink3 Lite offers simple RGB and CMYK color replacement on raster and vector data, as well as the ability to produce different color patterns. Moreover, various color replacement functions can represent desired colors.

* TxLink3 Lite or RasterLink6 is bundled according to a user’s choice.

Production Example of Tx300P-1800

*Click to view larger image.

|

|

|

|

|||

| Fashion Apparel | Interior fabrics | Seat fabrics | Outdoor equipment |

Model

| Tx300P-1800 | Maximum print width: 1,920 mm (75.6") |

|---|

Corresponding Ink

Sb420

Application list

- Tapestry

- Flag

- Sports Apparel

- Interior Fabrics

- Fashion Textile

-

Specifications

| Tx300P-1800 | ||

|---|---|---|

| Printhead | On-demand piezo head (4 in-line printheads) | |

| Print resolution | 360 dpi, 540 dpi, 720 dpi, 1,080 dpi, 1,440 dpi | |

| Maximum print width | 1,920 mm (75.6 in) | |

| Maximum media width | 1,920 mm (75.6 in) | |

| Ink | Type/Color | Sublimation dye ink:Sb420 (Bl, M, Y, K, Lbl, Lm) Disperse dye ink:Dd400 (C, M, Y, K, R, Gray, Violet, Pink) * Textile pigment ink:TP400 (C, M, Y, K, Bl, R, Lk, Green) * Reactive dye ink:RC400 (C, M, Y, K, Bl, R, Or, Lk) * Acid dye ink:AC400 (C, M, Y, K, Bl, R, Or, Lk) * |

| Package size | 2L Ink pack | |

| Media thickness | 1.0 mm or less | |

| Rolled media weight | 40 kg (88 lb) or less Please note that the above maximum weight applies on a printed roll including ink weight. |

|

| Certifications | VCCI class A, FCC class A, ETL UL 60950-1, CE Marking (EMC, Low voltage, Machinery directive, and RoHS), CB, REACH, Energy Star, and RCM |

|

| Interface | USB 2.0 Hi-speed / Ethernet 1000BASE-T | |

| Power supply | Single-phase AC100 – 120V / AC200 – 240V | |

| Power consumption | AC100V: 1.44kW / AC200V: 1.92kW | |

| Operational environment | Temperature: 20 – 30 °C (68 – 86 °F) Humidity: 35 – 65% Rh (Non condensing) |

|

| Dimensions (W × D × H) | 3,200 x 965 x 1,857 mm (126 x 38 x 73 in ) | |

| Weight | 255 kg (562.2 lb) | |

* Inks are available in the future

Ink set

| Sb420 [Bl,M,Y,K,Lbl,Lm] |

Bl M Y K |

|---|---|

| Bl M Y K Lbl Lm |

- Some of the samples in this website are artificial renderings.

- Specifications, design and dimensions stated in this website may be subject to change without notice (for technical improvements, etc).

- The corporate names and merchandise names written on this website are the trademark or registered trademark of the respective corporations.

- Inkjet printers print using extremely fine dots, so colors may very slightly vary after replacement of the printing heads. Also note that if using multiple printer units, colors could vary slightly from one unit to other unit due to slight individual differences.

- Depending on image files used for printing, the print quality would be affected when printing in a low-resolution mode with the lowest number of passes.

New printhead allows printing on various types of textile

While printing on raised fiber surface textiles, a high head gap setting is required to prevent contact between the printhead and the nap. In conventional models, such gap conditions reduce the accuracy of ink droplet placement. However, the new printhead ejects ink droplets at a high speed to maintain the straightness of the droplet direction, and accordingly accurate ink droplet placement is achieved. This enables high-quality printing on napped or thick textiles.

Reliable textile feeding mechanism ensures stable printing

Stable textile feeding and transportation are crucial for direct textile printing. The tension applied to the textile during printing is varied according to changes in the outer diameter of the front and rear rolls. The Tx300P-1800 monitors the applied tension and uniformly applies the optimum tension using the front and rear tension bars. Thus, high-quality printing is achieved during high-speed printing or even when using a large textile roll.

Mimaki’s print technologies for achieving beautiful printing

Mimaki Advanced Pass System 4 (MAPS4) reduces banding

Mimaki’s unique anti-banding technique MAPS4 is an advanced version of MAPS3. To prevent banding, swath boundaries are overprinted, whereas boundaries prone to banding are printed with fewer ink droplets.

Superior inkjet technology

Mimaki’s superior inkjet technology accurately places the ink droplets without losing their perfect circularity. This ensures that texts, lines, and edges are clearly and sharply printed.

Uninterrupted printing solutions

Continuous operation support pack minimizes the downtime

The Nozzle Check Unit (NCU) detects nonfunctioning nozzles and automatically cleans them. If the nozzles fail to operate after cleaning, defective nozzles are replaced by non-defective ones until a technician arrives, and printing is continued. This feature enables uninterrupted print operations and continuous productivity.

Standard features of MBIS3 and UISS deliver continuous printing for a long time.

Large two liter ink packs are installed in MBIS3*1 for long-time continuous printing to reduce operating cost.

As soon as one ink container is empty, UISS*2 automatically provides ink from another container without any interruption to printing.

These systems supply inkcontinuously to ensure unattended continuous printing.

*1 MBIS3: Mimaki Bulk Ink System3

*2 UISS: Uninterrupted Ink Supply System

Maximum print speed (68 m2/h) achieves high productivity

The Tx300P-1800 optimizes the printing speed and quality to produce the desired print results. For this purpose, it provides a wide range of printing modes, from the draft printing mode (which operates at the maximum speed of 68 m2/h) to high-quality printing mode.

A wide range of textile inks

Mimaki offers five ink types -sublimation, dispersant, pigment, reactive, and acid- to meet various application needs.*1

| Ink type | Product name | Color | Features | Applicable fabric |

|---|---|---|---|---|

| Sublimation dye ink | Sb420 | Bl, M, Y, K, Lbl, Lm | Sublimation ink for direct printing. No transfer paper is required. | Polyester |

| Disperse dye ink*2 | Dd400 | C, M, Y, K, R, Gray, Violet, Pink | Inks are fixed by heating and have high durability. | Polyester, nylon, acetate, and other fibers |

| Textile pigment ink*2 | TP400 | C, M, Y, K, Bl, R, Lk, Green | Simple post-printing process. No steaming, washing and drying processes are required. Inks are fixed by only heating. | Cotton, hemp, and other fibers |

| Reactive dye ink*2 | RC400 | C, M, Y, K, Bl, R, Or, Lk | Inks produce vibrant colors, reproduce a wide gamut of colors, and have water resistance, light-fastness, and rub-fastness because of dyestuff molecule bonding with the fibers. | Cotton, hemp, silk, rayon, and other fibers |

| Acid dye ink*2 | AC400 | C, M, Y, K, Bl, R, Or, Lk | Inks produce vivid and brilliant colors on animal fibers and synthetic protein fibers such as nylon. | Wool, leather, silk, nylon, and other fabrics |

*1 Please select an ink type depending on your intended use. The ink type cannot be changed after installation.

*2 Inks are available in the future.

Software

TxLink3 Lite or RasterLink6 is bundled according to user's request.

.jpg)

.jpg)