Product Information

TS500P-3200

- Liên hệ để biết giá

Reliable Mechanism for High Productivity

"TS500P-3200" operating at a high speed of 180 m2/h increases productivity and delivers beautiful quality printing on transfer paper up to 3.2 m wide. With its excellent capabilities, it meets a broad range of applications including home furnishing textiles and indoor soft signage.

- 3.2-m superwide sublimation inkjet printer

- The maximum printable width of 3.2 m is practical for sublimation transfer printing on extra-wide fabrics for curtains, bed linens, and other home furnishings.

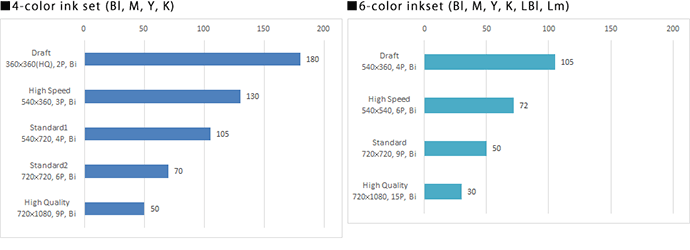

- The maximum printing speed (180 m2/h) achieves high productivity

- The maximum print speed is 180 m2/h*1 for 4-color printing and 105 m2/h*2 for 6-color printing.

*1 Print conditions: 180 m2/h, 4 color, Draft mode, 360 × 360(HQ) dpi, 2 pass

*2 Print conditions: 105 m2/h, 6 color, Draft mode, 540 × 360 dpi, 4 pass

- New printhead and feeding mechanism ensure high speed and quality printing on 3.2-m wide media

- 12 new-type printheads rapidly eject ink to ensure high speed, quality printing at high printhead gap settings.

- AMF*3 is capable of feeding media up to 3.2 m wide and of 130 kg. Moreover, AMF can maintain stable feeding to achieve high-quality printing.

- Cockling-reduction transfer mechanism*4 supports high-speed printing on a wide paper.

*3 AMF: Front and rear tension bars apply the appropriate tensions to the media in order to maintain stable media transportation.

*4 Cockling: Wrinkling of the media surface due to ink absorption. The printhead tends to make contact with the cockled paper surface when the head gap is narrow, resulting in undesirable contact damage to the printhead and inferior print quality.

- Uninterrupted printing solutions

- Nozzle Check Unit (NCU) automatically detects and cleans clogged nozzles.

- Nozzle Recovery System (NRS) uses only good nozzles as substitutes, when the clogged nozzles are not recovered after cleaning.

- The large ink containers (3 liters) are installed in the external ink supply unit. The inks can be filled into the container during long-time continuous printing.

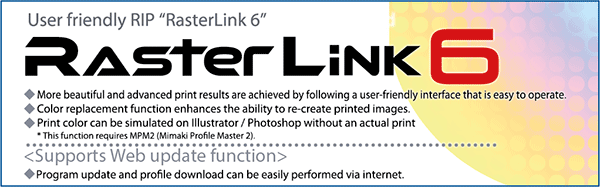

- High-performance RIP software TxLink3

The TxLink3 offers simple RGB and CMYK color replacement on raster and vector data, as well as the ability to produce different color patterns. Moreover, various color replacement functions can represent desired colors.

TxLink3 Standard or RasterLink6 is bundled according to user's request.

Mimaki subimation inkjet printer

Sublimation ink

Production Example of TS500P-3200

*Click to view larger image.

|

|

|

||

| Soft Signage | Fashion Apparel | Interior fabrics |

Model

| TS500P-3200 | Maximum print width: 3,290 mm (129.5") |

|---|

Corresponding Ink

Sb310

Application list

- Tapestry

- Flag

- Sports Apparel

- Interior Fabrics

- Fashion Textile

-

Specifications

TS500P-3200 Printhead On-demand piezo head (3 staggered arrangement) Print resolution X: 360 dpi, 540 dpi, 720 dpi, 1080 dpi

Y: 360 dpi, 540 dpi, 720 dpiMaximum print width 3,290 mm (129.5 in) Maximum media width 3,300 mm (129.9 in) Ink Type/color Sb310 (Bl, M, Y, K, Lbl, Lm) Package size 2 l bottle

*Large ink containers (3 l) are installed in the ink supply unitInk set 4-color: Bl, M, Y, K

6-color: Bl, M, Y, K, Lbl, LmRIP software RasterLink6, TxLink3 Standard, TxLink3 Professional * Media thickness 0.2 mm or less Rolled media weight 130 kg (286.6 lb) or less Certifications VCCI class A, FCC class A, ETL UL 60950-1,

CE Marking (EMC, Low voltage, Machinery directive, and RoHS),

CB, REACHInterface USB 2.0 Hi-speed / Ethernet 1000BASE-T Power supply Single-phase AC200 – 240V ±10%, 50/60Hz ±1Hz Power consumption 6,900W or less Operational environment Temperature: 20 – 30 °C (68 – 86 °F)

Humidity: 35 – 65% Rh (Non condensing)Dimensions (W × D × H) Main unit: 5,620 × 1,800 × 1,820 mm (221.3 × 70.9 × 71.7 in)

Ink supply unit: 950 × 510 × 730 mm (37.4 × 20.1 × 28.7 in)Weight Main unit: 1,500 kg (3,306.9 lb)

Ink supply unit: 30 kg (66.1 lb)* TxLink3 Lite is not compatible.

Ink set

Sb310

[Bl,M,Y,K,Lbl,Lm]Bl M Y K Bl M Y K Lbl Lm - Some of the samples in this website are artificial renderings.

- Specifications, design and dimensions stated in this website may be subject to change without notice (for technical improvements, etc).

- The corporate names and merchandise names written on this website are the trademark or registered trademark of the respective corporations.

- Inkjet printers print using extremely fine dots, so colors may very slightly vary after replacement of the printing heads. Also note that if using multiple printer units, colors could vary slightly from one unit to other unit due to slight individual differences.

3.2-m superwide format sublimation inkjet printer

The maximum mountable paper width is 3,300 mm and printable width is 3,290 mm. Generally, home decor fabrics for curtains, bed linens, and carpets are coordinated using the same printed patterns. However, the colors cannot be different when all of the coordinated fabrics are printed by the same printer.

Production of the same pattern for harmonized room design.

Maximum print speed (180 m2/h) achieves high productivity on 3.2-m wide transfer paper

FIG.1: Staggered arrangement

To achieve high printing speeds, 12 printheads are arranged in a staggered 3-line array. A range of printing modes is offered to suit the finished print appearance from a high-speed (180 m2/h) draft mode to a high-quality mode.

New printhead and feeding mechanism ensure high-speed and quality printing on 3.2 wide media

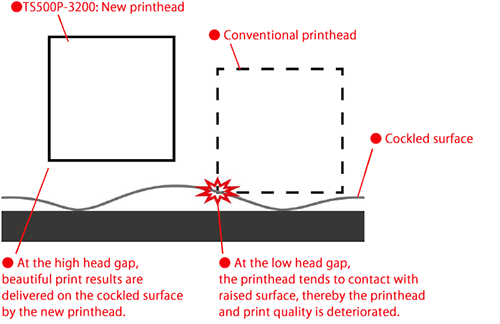

Cockling is well known to reduce product yield and quality and frequently occurs on transfer papers during printing. With its cockling-reduction transfer mechanism and new printhead, the TS 500P-3200 can print on cockled papers with a high head gap setting while maintaining beautiful print quality. Previously, thin papers were used for low-cost printing and thicker papers for high-quality printing. Now, the TS500P-3200 can simultaneously provide cost reduction and high-quality printing on both thin to thick papers.

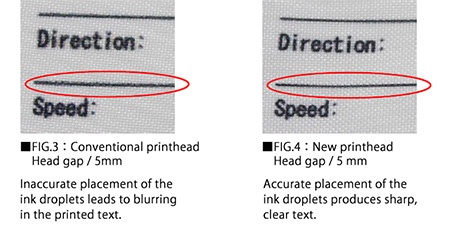

The new printhead with a high head gap achieves high-quality printing on cockled transfer papers

Low-cost thin transfer papers tend to cockle. To prevent contact between the printhead and raised surface, a high head gap setting is required (FIG.2). In conventional models, such gap conditions reduce the accuracy of ink droplet placement (FIG.3). The new TS500P-3200 employs a new printhead with a high head gap to ensure accurate ink droplet placement, thereby enabling high-quality printing on thin paper types (FIG.4).

FIG.2: Head gap

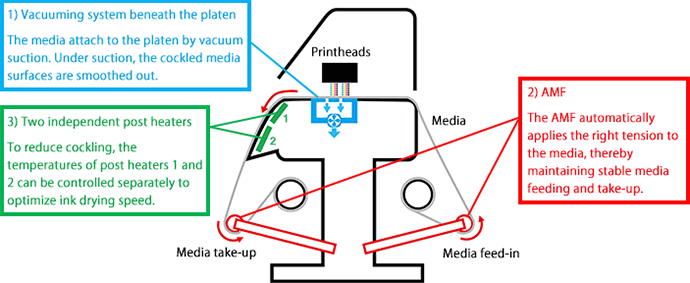

Cockling-reduction media transfer mechanism

1) The media attach to the platen by vacuum suction. Under suction, the cockled media surfaces are smoothed out.

2) Auto Media Feeder (AMF) automatically applies the appropriate tension to various types of the paper from thin to thick rolls up to 130 kg, thereby maintaining stable and precise media feeding/take-up for achieving high-quality print results.

3) Two post heaters are vertically installed on the front side to accelerate ink drying. The temperature of each heater can be controlled separately. To reduce cockling, the temperature of heater 1 can be lower than that of heater 2.

FIG.5: Section view of printer unit

FIG. 6: New design AMF

Mimaki’s print technologies for achieving beautiful printing

Waveform control technique assures beautiful printing

Each ink color has its own specific gravity and viscosity. To achieve precise placement of the ink droplets onto the media, Mimaki designed an optimum waveform that allows the printhead to jet each ink color at the appropriate jetting angle without losing excellent ink droplet circularity even at the high head gap. Moreover, various ink droplet sizes are precisely placed from the minimum size 6pl to the maximum size 24pl. Small droplets create beautiful high-resolution printing, and large droplets are very useful for high-speed printing. Thus, the TS500P-3200 satisfies a wide range of needs including beautiful high-quality printing and productive high-speed printing.

MAPS4 delivers stable high-quality printing

Generally, swath boundaries are straight lines. Therefore, a slight misalignment between boundaries causes banding or uneven color printing. MAPS4 reduces banding and uneven color printing with blurred boundaries similar to gradation printing.

Uninterrupted printing solutions

Ink and media shortage, clogged nozzles, and other minor problems influence stable productivity. The TS500P-3200 fully supports continuous printing with reliable technologies.

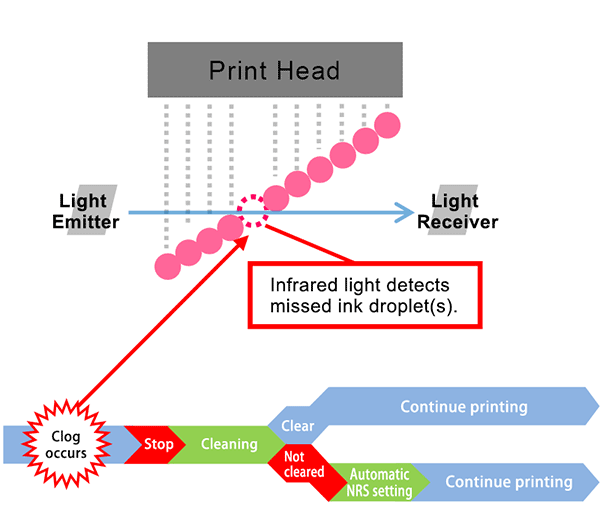

NCU automatically detects and recovers clogged nozzles

Clogged nozzles are detected automatically by monitoring ink droplets with sensors. When clogged nozzles are located, these are automatically cleaned, reducing waste printing. Nozzles are checked per transfer file.

NRS for maintaining productivity

If the clogged nozzles are not recovered after cleaning through the NCU function, the NRS selects substitute nozzles and then restarts printing. This is a significant novelty, since previously, when nozzle cleaning fails, the printhead has to be repaired by a technician, and the printing operation ceases until the printhead is repaired. The NRS allows the printer to continue printing without interruption by using non-defective nozzles as substitutes for defective nozzles until the technician arrives.*

* NRS may not be activated depending on print modes.

Built-in large (3 l) ink containers for long-time continuous printing

Large (3 l) ink containers are installed in an external ink supply unit. Ink can be filled into the container during long-time continuous printing. A degassing module is installed on the printhead carriage to allow the use of affordable undegassed inks.

Software

TxLink3 Standard or RasterLink6 is bundled according to user's request.

* TxLink3 Professional is optional.

* TxLink3 Lite is not compatible with TS500P-3200.

| Feature | TxLink3 Standard |

TxLink3 Professional |

RasterLink6 | |

|---|---|---|---|---|

| Multi printer connection | - | - | 4 | |

| Maximum printable spot colors | 4 | 4 | 3 | |

| Color replacement | Vector data | ○ | ○ | ○ |

| Raster data | ○ | ○ | - | |

| Color picker | ○ | ○ | - | |

| Target color measurement | ○ | ○ | - | |

| Swatch book | ○ | ○ | - | |

| Named color | ○ | ○ | ○ | |

| Profile creation | ○ | ○ | - | |

| Step and repeat | ○ | ○ | ○ | |

| Color combine | - | ○ | - | |

| Variable printing | ○ | ○ | - | |

| Ink color assignment for each slot | ○ | ○ | - | |

| Addition of seam lines | ○ | ○ | - | |

.jpg)

.jpg)

.jpg)