Product Information

CF2 Series

- Liên hệ để biết giá

Enable your multi-type-small-lot production with the CF2.

The CF2 Series flat bed cutting plotter capable of cutting various kinds of media with high accuracy without dies. Out of a total of 30 kinds of line-up, you can choose the one best suited for your needs. By cutting the printed media, you may produce high value-added products on demand required. Begin multi-type small-lot production with unprecedented high quality.

Line-up

We are prepared to make special equipment meeting your special application requirements. Please consult with our sales.

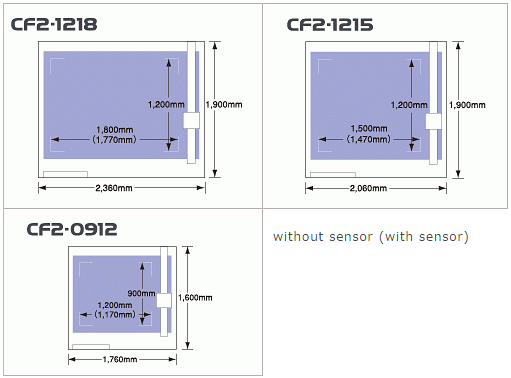

Size variation

* Please install this unit confirming that there is a space of 1,000 mm or more around the unit.

| CF2-0912** | CF2-1215** | CF2-1218** | ||

|---|---|---|---|---|

| Effective plotting area |

X (Sensor model) |

1,170mm(46.1") | 1,470mm(57.9") | 1,770mm(69.7") |

| X (No sensor model) |

1,200mm(47.2") | 1,500mm(59.1") | 1,800mm(70.9") | |

| Y | 900mm(35.4") | 1,200mm(47.2") | ||

| Motorization | X,Y,Z,θ 4 axes DC software servo | |||

| Maximum plotting speed | 50cm(19.7") / s | |||

| Maximum acceleration | 0.5G | |||

| Mechanical resolution | X:0.00234mm(0.00009") Y:0.003125mm(0.0001") θ:0.05625 | |||

| Command resolution | 0.025mm(0.001") / 0.01mm(0.0004") (changeable from operation panel) |

|||

| Static accuracy *1 |

Repetition accuracy | ±0.1mm(0.004") | ||

| Distance accuracy | ±0.1mm(0.004") or ±0.1% whichever is greater | |||

| Origin repetition accuracy | ±0.1mm(0.004") | |||

| Maximum thickness of set work | T / TD:25mm(1") RT / RC:20mm(0.8") | |||

| Work fixation | Air suction by a blower | |||

| Receiver buffer size | 1MB | |||

| Command | MGL-IIc3(Support MGL-IIc) *2 | |||

| Interface | RS-232C | |||

| Dimension | Width | 1,760mm(69.3") or less |

2060mm(81.1") or less |

2360mm(92.9") or less |

| Depth | 1,600mm(63.0") or less |

1900mm(74.8") or less | ||

| Height | 1,100mm(43.3") or less | |||

| Weight | 140kg(308lbs) | 165kg(364lbs) | 180kg(397lbs) | |

| Operation environment | Temperaturet : 5-40ºC Humidityt : 35-75%(Rh)No condensation |

|||

| Power requirement | Main Unitt : 50/60Hz AC100/120/220/240V(tap changing) Blowert : Stated separately |

|||

| Power consumption | Main Unit : 300VA Blowert : Stated separately | |||

- *1 Accuracy written with a pen where the load is almost non-existent. Guaranteed temperature range is 20 to 25 ºC.

- *2 A command based on HP-GL.

Materials that can be processed

Possible to cut with standard accessories

Possible to cut with standard accessories

Possible to cut with the use of optional items

Possible to cut with the use of optional items

| T | TF | RT | TD | RC | |

|---|---|---|---|---|---|

| Corrugated fiberboard(E to B corrugation)* |  |

|

|||

| Corrugated fiberboard(AB corrugation)* |  |

||||

| Coated board for packaging* |  |

|

|||

| Vinyl chloride for clear package* |  |

|

|||

| Plastic corrugated fiberboard |  |

|

|||

| Vinyl chloride sheet for signboard |  |

|

|

|

|

| Soft vinyl chloride(0.5 to 10mm) |  |

|

|||

| Reflecting sheet |  |

|

|

|

|

| Sand-blast rubber |  |

|

|

|

|

| Industrial sheet rubber(3mm or less) |  |

|

|

|

|

| Industrial sheet rubber(0.5 to 10 mm) |  |

|

|||

| Pattern Happort |  |

|

|

|

|

| Teflon(1.0 to 5.0mm) |  |

|

|

||

| Resin belt. (5.0mm or less) |  |

|

|||

| Various foam(20mm or less) |  |

- Note) As the property of the media may vary depending on the material manufacturers, the above data is just a guide. Make sure to perform your own testing.

- Note) *shows material to which drawing of the ruled line is possible.

Composite materials etc. can be half-cut.

Half-cut

By adjusting the depth of the cutter blade, you can half-cut composite, laminated material (etc). As two tools can be used, you can perform different types of half-cutting or diecutting without changing the tools.

Thick material can be outline-cut with high accuracy.

Mark-sensor function

With the adoption of a high performance color photo sensor, the round register marks printed on the media are detected and the position of the origin, inclination of coordinate and distance are adjusted.

This enables the operator to perform cutting at the precise position. Further, the sensor recognizes the difference of "color of media" and "color of round register marks", and enables the cutter to perform cuts accurately, while being tailored to the printed material without being influenced by the color of the media. A light pointer that is used as marker when setting the media is provided as standard device and facilitates position adjustment with round register marks.

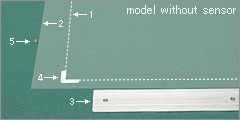

Media is set easily and accurately

With the aid of a work-guide installed to the directions of X and Y, the positioning of the media is smooth and working efficiency has been improved. It is also possible to remove the work-guide depending on the media size.

1: Effective range of cutting

2: Media

3: Work-guide plate

4: Origin seal

5: Work-guide pin

*For models with sensor, work-guide plate is used instead of work-guide pin.

*Please note that the work guide is used just as a guide for setting the media and it is not intended to guarantee the distance to the origin.

Extensive line-up of cutter blades

A wide variety of cutter blades tailored to various media are provided. As one machine can process with flexibility, expand your business opportunities.

Cutter blades in the marketplace can also be used.

As the low cost cutter blades can be used, the running cost can be reduced.

Full of useful functions to support cutting

Correction of starting and ending points

The starting and ending positions of cutting are corrected, which makes cut-away of the media smoother. Adjustable within the range of 0 to 2.5 mm.

Circle θcorrection

Declination of starting point and ending point of a circle cutting caused by thickness or hardness of the media is corrected and cutting nearly perfect circle is available.

Press correction

Pressure of tool coming down is corrected to ensure complete cutting.

Repeated cutting

Is capable of repeating the cutting up to maximum of 5 times changing the cutting pressure. With only one time of data sending, you can cut eventhick material with high quality finish.

Back cutting

Back cutting is also possible by attaching mark chips to the back surface. From the front surface, excess cut is not seen making the finish beautiful.

Multiple registration of cutting conditions

Cutting conditions such as pressure, speed, scorrection of starting and ending points, circle θcorrection, offsets, etc. by tool may be registered for multiple times.

Various accessories

●Provided with felt mat required when reciprocal cutter is used.

*Provided with CF2-RC/RT as standard items.

●Various holders are available to meet a variety of material.

●Provided with a blower to securely suck and fix the media.

*Enhanced blower is also available as option.